For your building projects, are you trying to find a quick and economical way to produce high-quality bricks? It could be worth considering using a Fly Ash Brick Making Machine. Everything you need to know about Fly Ash Brick Making Machine —their types, applications, and advantages—will be covered in this blog post.

The benefits of using Fly Ash Brick Making Machine are numerous, which is why the building industry is adopting them more and more. Using Fly Ash Brick Making Machine has the following benefits:

Eco-Friendly:

Fly ash is a by-product of coal combustion that that is not intended for landfills. You can contribute to waste reduction and sustainability by using fly ash in the brick-making process.

Cost-Effective:

In comparison to conventional clay bricks, fly ash bricks are less expensive, and the machinery used to make them requires less maintenance. They are therefore a reasonably priced choice for building projects.

High-Quality Bricks:

Bricks manufactured with fly ash are robust, long-lasting, and weather- and moisture-resistant. Additionally, their consistent size and shape make them simpler to work with in construction.

Various Fly Ash Brick Making Machine Types Fly ash brick production machines come in a variety of designs, each with its own special qualities and advantages.

Here are the three most common types of fly ash brick making machines:

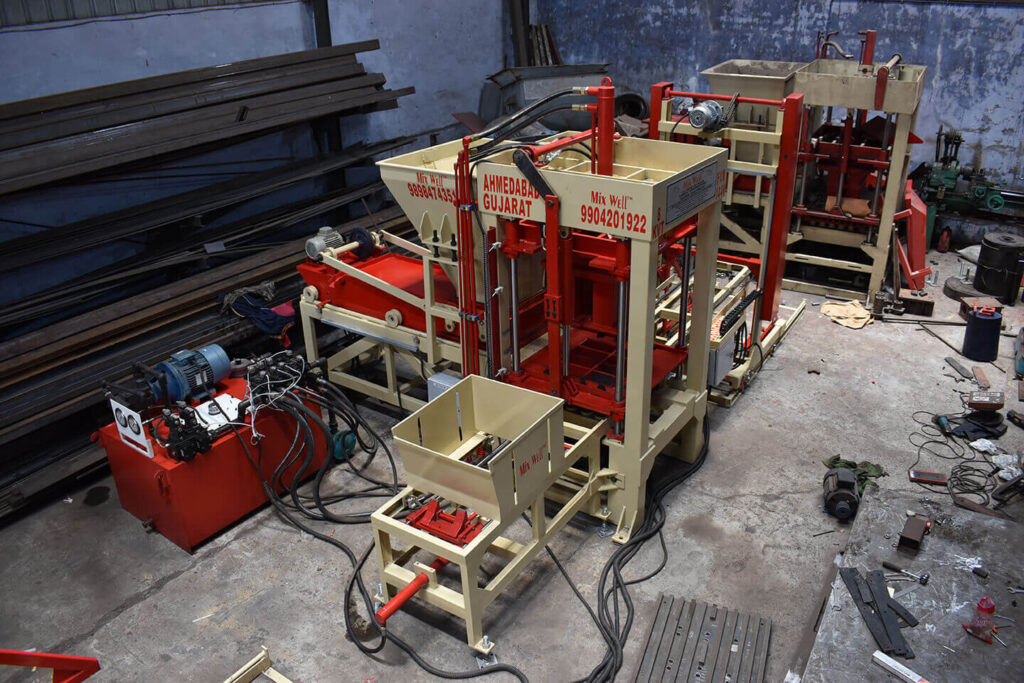

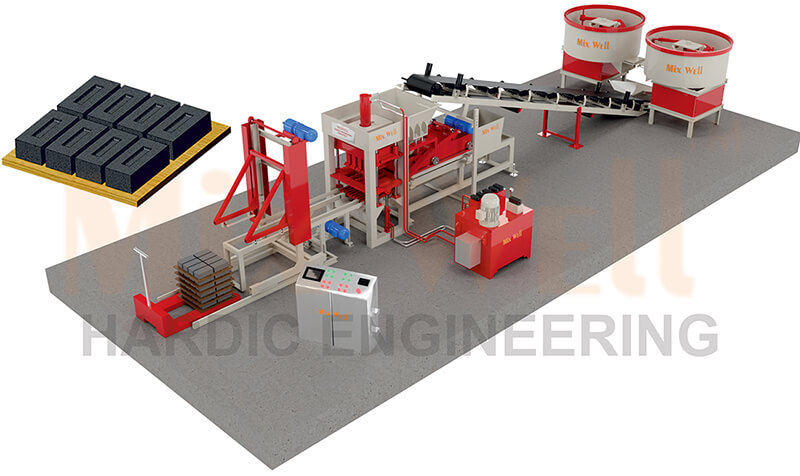

Fully Automatic Fly Ash Brick Making Machine :

This kind of machine requires minimal human intervention and is completely automated. Capable of producing up to 14,000 bricks per hour, it is appropriate for production on a large scale.

Semi-Automatic Fly Ash Brick Making Machine :

Although this kind of machine has lower running costs than fully automatic machines, it still requires some manual intervention. With a maximum production capacity of 8,000 bricks per hour, it is appropriate for medium-sized production.

Manual Fly Ash Brick Making Machine :

Although this kind of machine is the least expensive, it needs a lot of manual labor. It is appropriate for small-scale production and has an hourly capacity of 2,000 bricks.

Uses for Fly Ash Brick Manufacturing Equipment Numerous construction projects employ fly ash brick making machine , such as:

Residential Buildings:

Fly ash bricks are a common material for building homes because of their affordability, strength, and durability.

Commercial Buildings:

Additionally, fly ash bricks are utilized in the construction of business structures like malls, hotels, and offices.

Infrastructure Projects:

Fly ash bricks have a high strength and resistance to moisture, which makes them useful for building roads, bridges, and other infrastructure projects.

Conclusion

Bricks for construction projects can be produced in an environmentally responsible, economical, and high-quality manner with fly ash brick making machines. You can choose the right machine for your project by being aware of the features, kinds, and applications of fly ash brick making equipment. Bricks that fulfill your construction requirements can be produced by fly ash brick making machines, whether you require a fully automatic, semi-automatic, or manual machine.