Fly Ash Brick making machine play a vital role in brick production and in a construction industries. These devices are designed to use fly ash, a coal combustion byproduct, as a raw material to make high-quality bricks. Fly Ash brick making machine are help to produce cost effective, high quality and eco-friendly building materials.

Fly Ash Brick making machine are used to setting up brick plant where we mix raw materials and combined them to mold into bricks of desired shapes and sizes. Fly Ash Brick making machine allow us to contribute in sustainable construction practices by lower dependency on clay brick. Additionally, by using this machine, we reduce environmental pollution brought on by incorrect fly ash disposal.

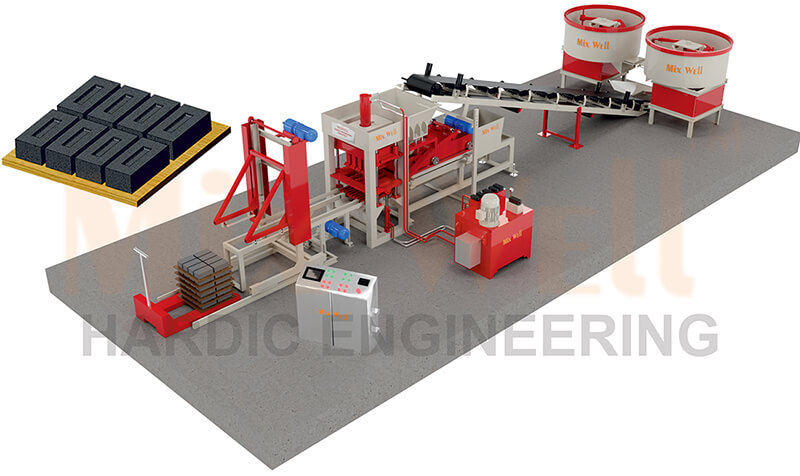

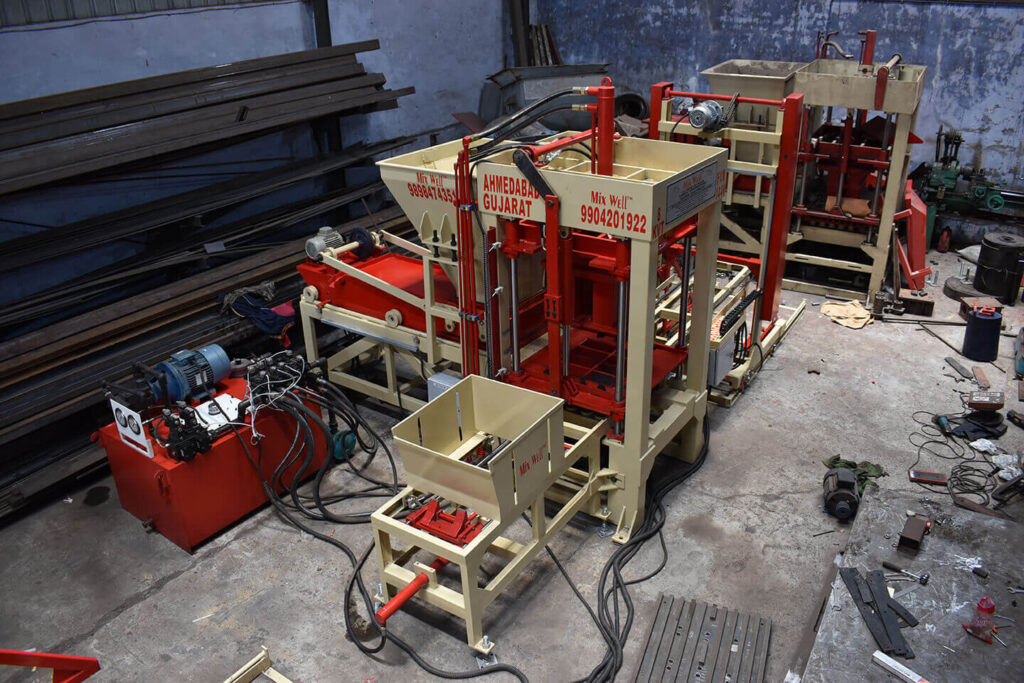

Fly Ash Brick Making Machine Working Process & Components

Fly Ash Brick Making Machine are equipped with components that work together to produce high quality brick efficiently.

There are several staged include in working process of Fly Ash Brick Making Machine. The raw materials such as fly ash, water, cement & sand are mixed in specific relative amount in the machine’s mixer. After that, This Mixer transform into Bricks are formed. There are important parts of Automatic Fly Ash Brick Making Machine includes Conveyor belts for feeding raw materials, pan mixers for thorough mixing, hydraulic systems for compaction and remolding automatic control systems for precise operation. On the other hand, manual intervention at certain stages of the process required to semi-automatic brick manufacturing machines.

It is important to know that every components of Fly Ash Brick Making Machine play essential role to ensuring the efficiency and quality of the final product. necessary process such as Regular maintenance and proper operation of components are maximize work output and extend the life of machine.

Advantages of Using Fly Ash Bricks and How Sustainability Is Affected by the Machine

The construction industry has seen a rise in the use of fly ash bricks because of their numerous advantages.

Fly ash, a waste product that ends up in landfills, is used to make these bricks, which helps to reduce negative effects on the environment and encourage sustainable construction method. Fly ash bricks are more environmentally friendly than clay bricks because they require less energy to produce. In addition to being stronger and more durable during the building process, fly ash bricks absorb less water than clay bricks, which makes them ideal choice for construction process also this machine reduce maintenance costs over time. Although, these bricks have superior thermal insulation qualities, which raise building energy efficiency.

Fly Ash Brick Making Machine combines sustainability and eco friendliness to make them an attractive choice for environmentally conscious construction.

Types of Fly Ash Brick Making Machine: Manual vs. Automatic

There are two types of machine and both are setting their different advantages and considerations that help us to choose right fly ash brick making machine for our business.

Manual fly ash brick making machine are relatively more affordable with simple design. This machine require more manpower that’s why it is suitable for small scalp production. Manual Machine are perfect for startup or small/limited budget business

However, Automated brick making machine provides increased output and quality of production. These Machine are equipped with advance components such as mixing, automatic feeding, pressing and stacking. This Machine require less manpower and it is suitable for large scale businesses.

There are many types of Automatic Brick Making Machine such as Hydraulic fly ash bricks machines and Fully Automatic Fly Ash Brick Making Machine. These all machine are producing fix amount of bricks in a certain time that help to labor availability and time.

Best Practices and Maintenance Tips to get Ideal performance of Brick Making Machine

There are several important tips and best practices to ensure longevity and optimal performance

Regular Cleaning : One of the most important part to get ideal performance is to cleaning fly ash brick making machine consistently. Dust can affect on machine efficiency. Make sure you clean all parts of the machine regularly including molds, conveyor belts & mixing chambers.

Lubrication : Properly lubricate the moving part in the fix decided time, read manufacturing guidelines for recommended lubricants for various components of the machine.

Find and Solve Common Issues : Try to Familiarize yourself with common issues such as blockages in material feeder. And learn to address these issues promptly by yourself.

Inspect Wear Parts : inspect wear parts such as molds, blades & conveyor belts and replace any worn out parts to avoid interrupt in production.